How are Gold Coins Made?

Minting is the official process of making coins, and when it comes to gold coins, it is a particularly important procedure. Gold Coins come in various types, from those meant for investment, like the UK Britannia and Sovereign or the South African Krugerrand, to special editions for collectors. Understanding how these coins are made can give insight into their value and appeal. Read on for a step-by-step guide to the minting process of gold coins.

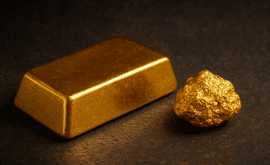

What are gold coins made of?

Coins such as the UK Britannia and Canadian Maple Leaf are struck in pure, 24 carat fine gold with a fineness of 999.9 (out of 1000). Others, like the UK Sovereign and the USA Eagle are crafted in 22 carat gold and hold a fineness of 916.7. The remaining metal in these alloyed coins is usually copper or silver.

Non-24ct gold coins are often alloyed with other metals such as copper in order to make them more durable. Pure gold is considered a soft, malleable metal, making it vulnerable to damage when handled often.

Gold has been used to make coins for thousands of years and is believed to have been first used in the 6th century BC in Lydia, a kingdom of western Asia Minor. Gold coins later gained popularity in Europe during the Middle Ages and were predominantly made of almost pure gold. However, gold’s use as a primary form of currency ended in the early part of the 20th century with the abandonment of the gold standard in 1933, leading to a permanent halt in the production of gold coins for circulation. Since then, gold coins have primarily been minted for those looking to buy gold bullion for investment or collectable purposes, with modern minting techniques improving both the quality and available variety of coins.

The process of making a gold coin

Before it makes its way into a collector's hands or portfolio, a gold coin must undergo a journey from raw material to a finished piece of numismatic art. The process of crafting a gold coin involves a mixture of tradition, creativity, and precision engineering, with each step playing a crucial role in the production of these coveted assets.

Step 1: Designing a coin

Firstly, a new coin is commissioned by the mint, and then gifted technical artists create and draw out a selection of designs. This is especially significant in the case of commemorative gold coins, where the design often reflects a significant event such as a royal birth, a coronation or jubilee, or a historical figure. From these first concepts, an artist’s design will be selected, carefully considering its visual impact.

Following the selection of the design, a sculptor will then create a large three-dimensional clay sculpt many times larger than the actual size of the coin, in order to perfect the design to the finest detail. Once the clay model is finalised, plaster is poured over it to create a mould, capturing every intricacy of the design.

Step 2: Creating a die

The plaster model is coated with rubber which is used to make an epoxy resin mould. This mould is then mounted onto a transfer-engraver machine which reduces the design to actual coin size and transfers the image onto a steel blank called a ‘master hub’.

Heat treated metal is placed under a lathe and smoothed into a measured blank die. The master hub is pressed into this die, creating the ‘master die’. This master die is then used to create working hubs, which are put through the same process to create the working dies - these are the dies used for the actual striking process. The difference between a hub and a die is that the hub has a raised image, and a die has an incuse image - one forms the other.

Step 3: Preparing the gold

Pure gold is heated in a furnace to 1,064 degrees Celsius to ensure it can be melted, and then poured into cylindrical billets. These billets are then made into long, thin strips and cut into smaller lengths, before being sent into a blanking press that punches the gold or silver strips into discs known as ‘blanks’ (also known as ‘planchets’ or ‘flans’). Each blank is weighed to ensure the final coin weighs the correct amount. The blanks are then washed and polished to a brilliant lustre suitable for coining.

Step 4: Striking the coins

Each blank is carried along a conveyer to the coining press, where a steel collar is then inserted into the press around one of the dies. Hundreds of tons of air pressure push the blank into the collar, whilst the overhead die is forced down onto the blank. This large impact causes the formation of impressions on both sides of the coin, which is now ready for inspection.

Coining presses vary in size, from those that stamp one coin at a time, to others that stamp four coins at one time. Presses can strike from 120 up to around 400 coins per minute.

The patterned edge of gold coins (also known as ‘reeding’ or ‘milling’) is typically done using a collar, which holds the blank planchet in place while the obverse and reverse dies strike the main design onto the coin's faces. As the coin is struck, the collar also presses against the edge of the coin, creating the desired pattern. This not only adds a decorative element to the coin, but also helps to prevent counterfeiting.

What are proof coins and how are they made?

Proof coin blanks are polished and are struck using a die which has also been specially polished. Whereas a bullion coin will be struck once, a Proof coin blank is struck more than once, giving extremely fine detail to the coin. These coins are then carefully packaged to ensure they are not touched by bare hands.

Proof is the best minting quality available, characterised by the raised motif which stands out from the mirror-like surface of the coin. Proof coins also feature a matte or frosted finish to the design, contrasting with the shiny background, which is known as a ‘cameo’ effect. Proof coins are usually supplied in presentation boxes with certificates of authenticity, sometimes fetching a higher premium than bullion coins as they are prized by coin collectors.

Mint-made errors

On rare occasion, errors can be made during the minting process. These errors can be the result of broken or deteriorated minting equipment, malfunctions during the minting process, or purely by accident. Mint errors are rare, and gold examples are almost impossible to find due to the extra care taken whilst striking these pieces of such high value. Although previously looked down on by collectors for being ‘imperfect’, these mint-error gold coins can attract interest by those looking to collect error coins due to their rare or unique nature. As a result, the value of some of these coins can be driven up, depending on the rarity, the type of error, and the condition of the coin.

Some well-known examples of error coins include:

1802/01 Draped Bust Quarter Eagle Overdated Gold Coin

An overdated coin occurs when a date or part of a date is punched into a finished working die that would have already featured an earlier date. This sometimes occurred due to a shortage of dies or to save time and labour at the mint. It is estimated that there are only around two hundred examples of US Mint overdated coins, making them a valued and much desired coin by collectors. An example of this overdated 1802/01 eagle coin was sold at auction in 2005 for $115,000.

Overdated coins are early examples of mint error coins. Modern technology has removed the chance of this occurring today by mints including the correct date on the master die.

1906 Indian Head Cent Struck on Mexican 5 Pesos Gold Coin

In 1906, the US Mint began producing coins for Mexico. This year also saw an extremely rare, potentially unique, minting error where the Indian Head penny design was struck over a Mexican 5-peso gold coin. This is identifiable by the edge inscription which reads ‘Independencia Y Libertad’ instead of the standard plain edge of an Indian Head cent. This was an amazing find by a collector searching through bulk USA coins at a coin show.

This 1906 coin was sold at an online auction in 2022, with a winning bid of $72,500.

From the initial design process, to the final striking of each coin, the minting of gold coins is a blend of tradition, innovation, and skilled craftsmanship. Whether it is the pure 24ct gold Britannia, the 22ct gold Sovereign, or a commemorative proof coin, every step of the minting process is carried out with great care and attention to detail, ensuring quality and visual appeal for the final product.

From their beginnings in ancient Lydia, to modern technological minting techniques, the allure of gold coins has never faded, as they continue to offer a glimpse into history as well as a tangible asset appealing to collectors and investors alike.

Not sure which coins are best to buy? Read our article about the Five Best Gold Bullion Coins for UK Investors

Here at Atkinsons, our experienced team are here to help if you need a little more information on buying gold. Give us a call on 0121 355 0620 or send an email to info@atkinsonsbullion.com.

This blog represents one person’s opinion only. Please note, gold and silver prices may go down as well as up. Atkinsons Bullion & Coins accepts no responsibility for any losses based on information we have provided. We do not offer investment advice. Please carry out your own research before making an investment decision.